If you are planning to work with a factory in China, a factory audit is a crucial step to ensure the reliability and quality of your supplier. A factory audit in China is a comprehensive review the following of a supplier:

- Their facilities

- Their management systems

- Their production processes.

Also, it helps to assess the supplier’s capability to meet your requirements and avoid potential risks associated with manufacturing in China. In this article, we will explore a few things that you need to examine during your China factory audit.

Factory Facilities

One of the most critical factors to examine during a China factory audit is the factory facilities. The factory facilities should meet your quality standards and comply with local laws and regulations.

- The first thing you need to examine is the factory’s size, layout, and infrastructure. A factory with a well-designed layout and ample space indicates that the supplier has invested in infrastructure and equipment, which could lead to better production efficiency and quality.

- The next thing to examine is the cleanliness and maintenance of the factory. A clean and well-maintained factory demonstrates that the supplier takes pride in its work and has a high level of attention to detail.

- You should also check the safety equipment and procedures in place to ensure that the workers are safe and protected from potential hazards.

Management Systems

The next thing you need to examine during a China factory audit is the supplier’s management systems. A well-managed factory is more likely to meet your requirements and deliver quality products consistently.

- The first thing to examine is the supplier’s quality management system (QMS). A QMS is a set of policies, procedures, and processes that ensure that the products meet the specified quality standards. You should verify that the supplier has a documented QMS and that it is implemented effectively.

- The next thing to examine is the supplier’s production planning and control system. A robust production planning and control system ensure that the production processes are efficient, and the products are delivered on time.

- You should also examine the supplier’s planning and control processes to ensure that they are adequate for your requirements.

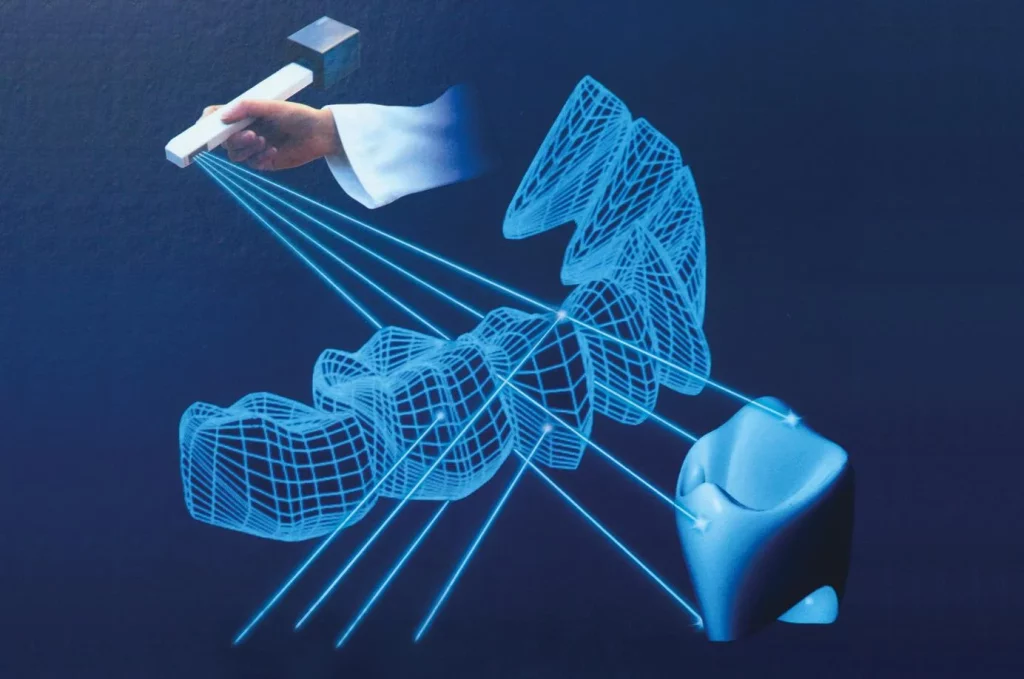

Production Processes

The production processes are the core of any factory audit. You should examine the supplier’s production processes to ensure that they are capable of producing the products that meet your requirements.

- The first thing to examine is the supplier’s production capacity. You should verify that the supplier can produce the required quantity of products within the specified timeframe.

- The next thing to examine is the supplier’s product quality control processes. A supplier’s quality control processes should be in place to ensure that the products meet your specified quality standards. You should examine the supplier’s quality control procedures to ensure that they are adequate and effective.

Documentation

Documentation is an essential part of any China factory audit. You should examine the supplier’s documentation to ensure that it is complete and accurate.

- The first thing to examine is the supplier’s business license and registration. You should verify that the supplier is a legitimate business and that it is registered with the relevant authorities.

- The next thing to examine is the supplier’s product documentation. The product documentation should include specifications, drawings, and other relevant information that will help you understand the product’s design and manufacturing process. You should examine the supplier’s product documentation to ensure that it meets your requirements.

Conclusion

A China factory audit is an essential step in ensuring that your supplier can deliver quality products that meet your requirements.

You should examine the factory facilities, management systems, production processes, and documentation during the audit to ensure that the supplier is capable of meeting your requirements.

By taking time to examine these factors, you can avoid potential risks associated with manufacturing in China and ensure a successful business relationship with your supplier.